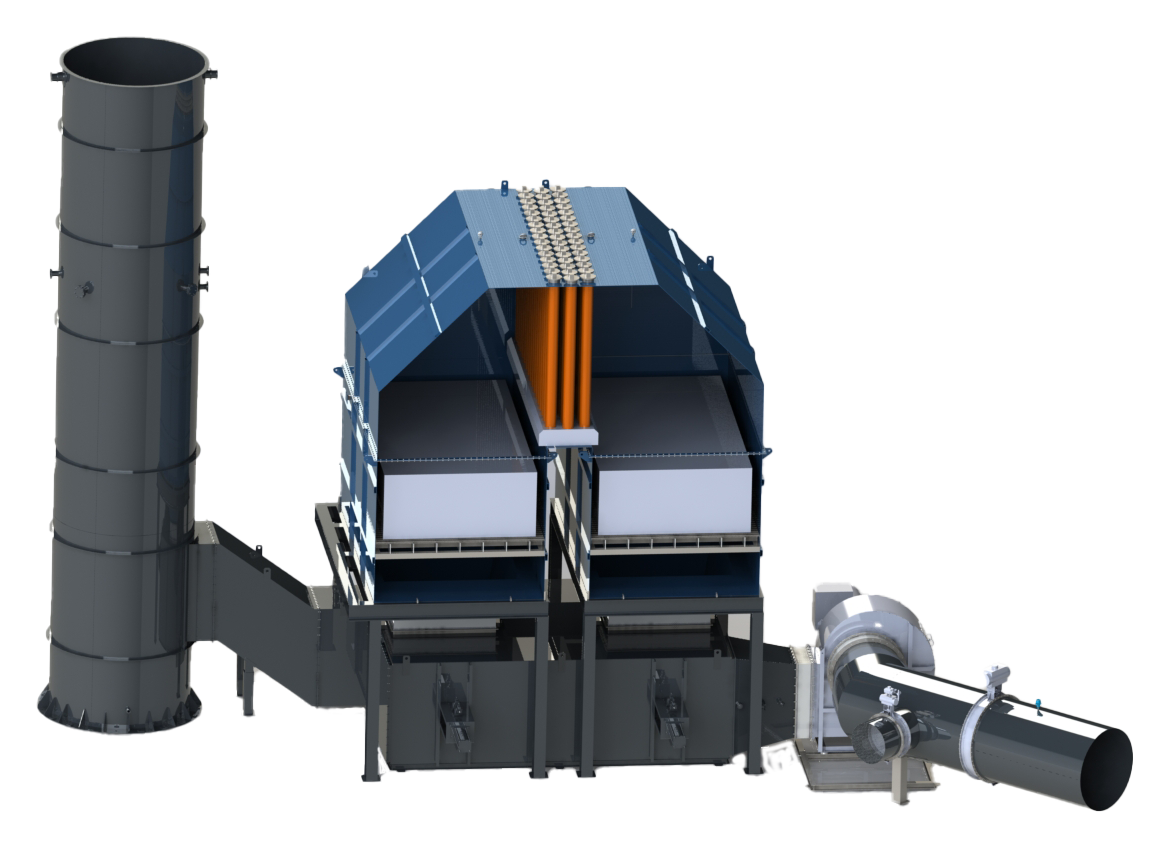

Electric Oxidizers. Defined.

Aeros VoltOx ecoRTO is an electric alternative to traditional Regenerative Thermal Oxidizers and eliminates any new source emissions onsite. It is a safe, simplified, solution designed to reduce an organization’s natural gas consumption and its carbon footprint.

This specialized electric regenerative thermal oxidizer (RTO), system has all the capabilities of a traditional RTO while adding the benefits of being a flameless solution. Aeros VoltOx ecoRTO offers a solution to eliminate the use of natural gas by removing the natural gas burner and replacing it with an electric heating element.

Conifer Systems is dedicated to revolutionizing the emissions control market as an original equipment manufacturer, through the introduction of innovative solutions that encourage environmental stewardship in voluntary and regulatory markets. The Aeros VoltOx ecoRTO (trademark) offers a solution in supporting organizations who wish to reduce their greenhouse gas emissions. Our electric regenerative thermal oxidizer (ecoRTO) enables organizations to work towards their sustainability goals by eliminating NOx and CO emissions from natural gas burners and adopting fully electric solutions. By implementing the Aeros VoltOx ecoRTO, and replacing dependency of natural gas burners in thermal oxidizers, companies can reduce their greenhouse gas emissions.

- Efficient

The Aeros VoltOx ecoRTO is an innovative solution that does not compromise on the effectiveness of traditional regenerative thermal oxidizers while enhancing the overall safety. This electric technology operates without a combustible fuel source. By eliminating the burner and becoming flameless, the Aeros VoltOx ecoRTO removes the equipment failures which can be associated with operating on natural gas. This design also reduces the need for hazardous areas, as the solution has no gas train.

- Simplified

The simplified design of the Aeros VoltOx ecoRTO is comprised of fewer subsystems, making it more reliable than the traditional regenerative thermal oxidizer. Unlike traditional RTOs, this electric solution has no purge or other NFPA requirements, no gas train, no need for combustion air, and no burner management system because it has no burner. This makes tuning and daily operation easier. Additionally, the Aeros VoltOx ecoRTO incorporates modular heating elements for easy maintenance. Overall, the simplified design of the Aeros VoltOx ecoRTO makes it more convenient for daily operation.

- Lower Energy Consumption and GHG Emissions

Shifting to electric energy instead of natural gas can help to reduce the greenhouse gas emissions of an organization’s overall operations. The transition to electric energy can significantly reduce emissions such as carbon monoxide, carbon dioxide, and nitric oxide (NO) and nitrogen dioxide (NO2). The Aeros VoltOx ecoRTO operates without the incremental emissions from the oxidation process and does not produce additional NOx from tailpipe emissions. This results in no incremental emissions to be considered onsite. The overall energy input for the equipment is also reduced by 4%-5% because 100% of heat is applied to process air, without any extra mass from combustion air or fuel gas.

- Advantages

- Flameless Regenerative Thermal Oxidizer

- Meets or exceeds destruction removal efficiency (DRE) and thermal efficiency of traditional, gas-burning thermal oxidizer

- Flameless design means no new emission source, including NOx or CO emissions, and lower CO2 emissions by eliminating natural gas combustion for 4%-5% reduction in overall energy input

- More efficient use of energy because 100% of heat is applied to process air, without any extra mass from combustion air or fuel gas

- Simplified design compared to a traditional regenerative thermal oxidizer results in no NFPA requirements and eliminates the need for burner management systems, combustion, gas train, and related components

- Hybrid options are possible for optimized operational costs with the use of Supplemental Fuel Injection for streams that need to be enriched

- Technical Details

- Standard design achieves 97% Thermal Efficiency

- 95%-98% Destruction Rate Efficiency

- Standard offering flow rates up to 60,000 SCFM with ability to increase capacity if needed

- Less than 1.5 MW connected load for 60,000 SCFM unit

- 10-hour start-up time for standard unit offering. Start-up times will vary based on the size of the heater selected and VOCs present in the process stream

- Qualities/Selling Points

- More efficient and cost-effective than natural gas alternatives because 100% of heat is applied to process air vs. heating the burner combustion air

- Reduces overall energy input by 4%-5% over traditional RTOs

- Lower NOx or CO emissions, and lower CO2 emissions by eliminating natural gas combustion

- Silicone carbide heating elements rated for surface temperatures of up to 2,900 °F

Empowering industries to create a more sustainable future.

+1 (832) 476-9024