Fugitive Emissions. Redefined.

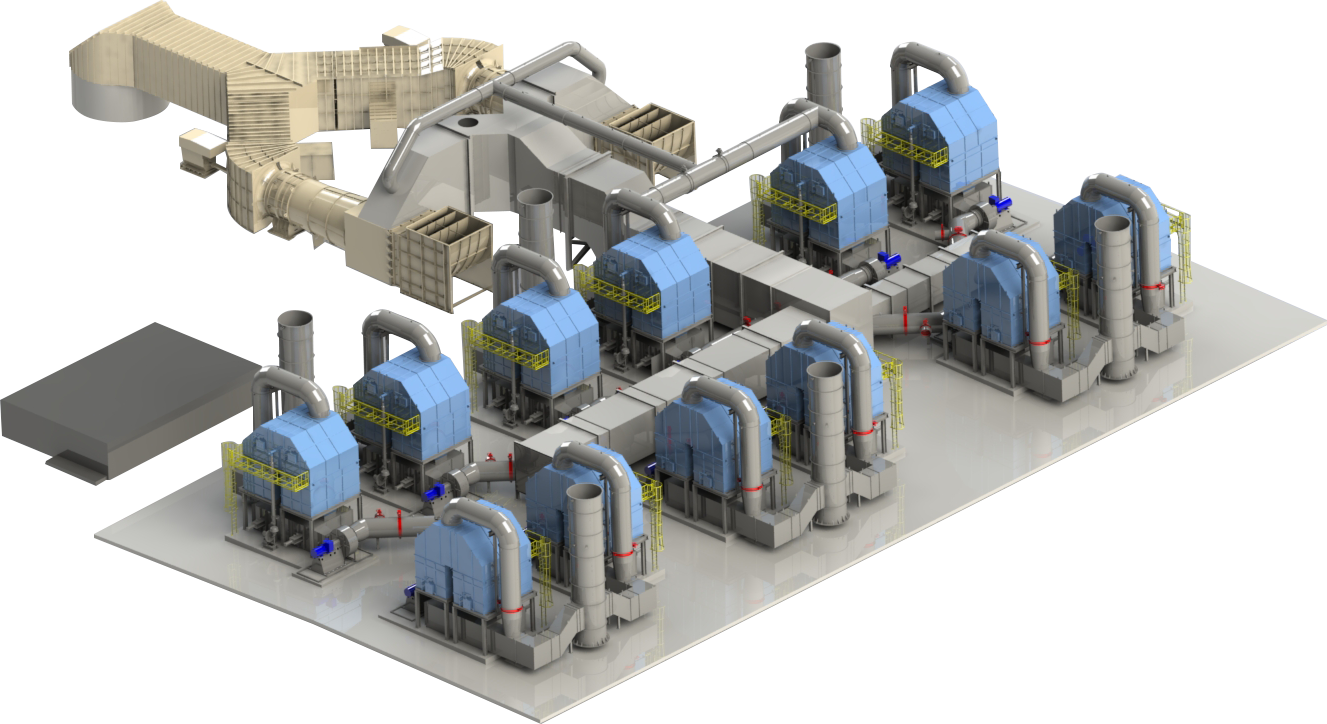

Aeros MineOx is a robust, reliable, and scalable solution specifically designed to destroy fugitive emissions and greenhouse gases (GHG) in large volume ventilation air mining applications.

This specialized Regenerative Thermal Oxidizer (RTO) system is capable of auto-thermal operation in applications where methane concentration is as low as 0.2%.

Conifer Systems has developed a solution to address the specific challenges associated with high-volume, low-concentration ventilation air methane applications. Aeros MineOx is a high thermal efficiency, low pressure drop solution that provides for autothermal operation from 0.2% to 1.2% methane concentration by volume. Maintaining autothermal operation through the entire operating spectrum is important as it reduces burner fuel consumption and site-generated emissions.

Whether forced or induced ventilation applications, vertical or horizontal upcast arrangements, Aeros MineOx seamlessly integrates with existing mine shaft infrastructure without disrupting normal mining operations.

- Robust

Aeros MineOx destroys 95% or more of methane while operating without supplemental fuel in an autothermal condition when methane concentrations are as low as 0.2%. This is due to the optimized thermal efficiency and the hot gas bypass system that works to manage heat release and operating temperature.

Aeros MineOx is designed to operate in hazardous environments and harsh operating conditions without the need for supplemental heating or cooling and can be operated remotely, streaming data to remote users via Internet-based, customizable dashboards. An auto-start function enables Aeros MineOx system operation in remote or unmanned installations.

- Scalable

With an innovative modular design and true IoT networking, Aeros MineOx can be scaled to meet any total methane destruction demand. Aeros MineOx units can be connected in parallel to a common ventilation air source ductwork system and networked via Ethernet to the local control room.

- Reliable

The dewpoint control system recovers heat from the methane destruction process, reinjecting hot gas into the common ventilation air source ductwork upstream of the Aeros MineOx system. By controlling the dewpoint of the ventilation air stream, Aeros MineOx suppresses condensation formation which provides flow and operational assurance by significantly reducing the risk of corrosion and ceramic media fouling.

With its advanced data logging and trending capabilities, Aeros MineOx systems are the ideal solution for fugitive emission applications where continuous emissions monitoring is critical. The harsh environment operating capabilities reduce total installed cost and make reliable operation possible in remote or unmanned installations including ventilation air methane destruction applications.

- Cost Effective, Affordable and Available

- Aeros MineOx delivers more value at a lower cost than other solutions available on the market.

- Aeros MineOx is built around Conifer’s monolithic poppet design, delivering to site a fully assembled and tested flow control system which significantly reduces installation time and cost.

- Aeros MineOx utilizes field-mounted remote input/output panels to reduce installation time and cost and our dewpoint control system reduces both CAPEX and OPEX investment. An arrangement of shared exhaust stacks also significantly reduces manufacturing, transportation, and civil construction costs.

- Aeros MineOx systems are designed and manufactured in the United States, deploying a vertically integrated manufacturing philosophy supported by domestic supply chain partners to deliver advanced abatement solutions with a focus on speed to market.

Empowering industries to create a more sustainable future.

+1 (832) 476-9024