Renewable Natural Gas

- SITUATION

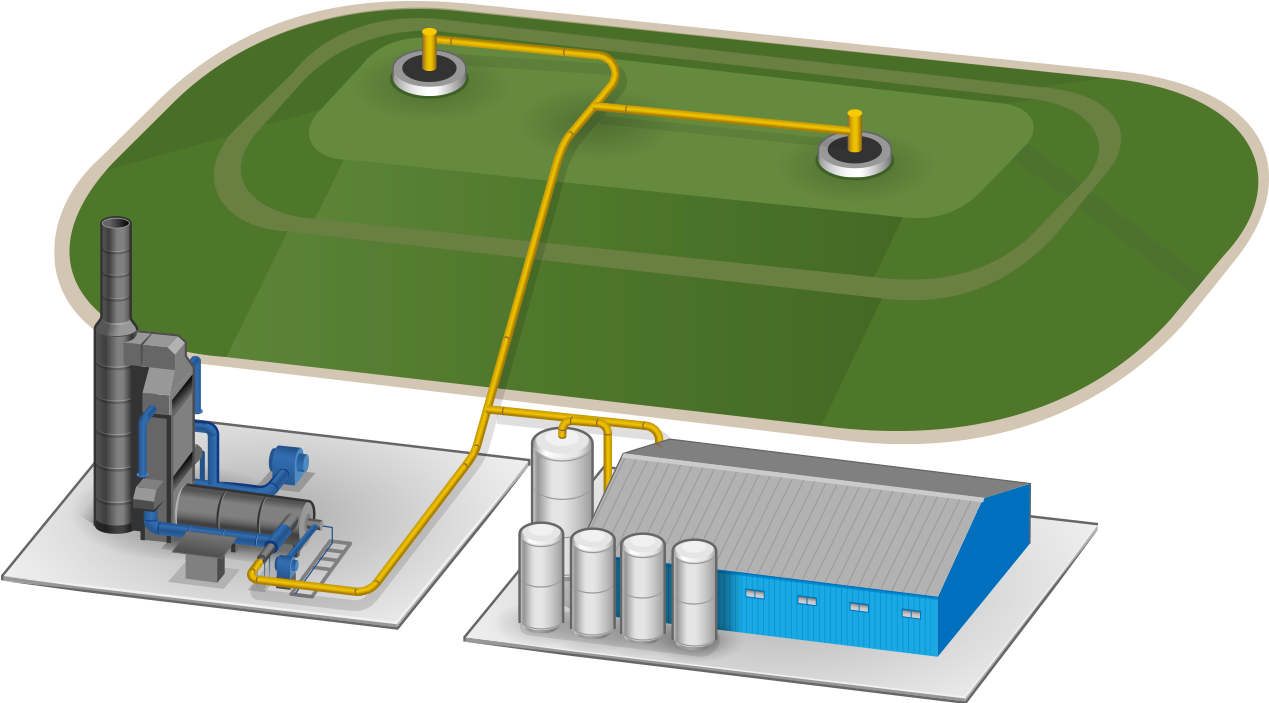

A large producer of renewable natural gas (RNG) needed a solution for volatile organic compound (VOC) abatement and biogas processing at a landfill in Medora, Indiana. The producer required a system that could operate continuously and met or exceeded pollution regulations for landfills, to tap into landfill RNG revenue opportunities.

Renewable natural gas is biogas that has been cleaned to a purity level consistent with brown natural gas and can be readily distributed via existing pipeline. RNG also qualifies as an advanced biofuel under the Renewable Fuel Standard (D3 RINS).

- SOLUTION

Our team of engineers designed a 3,000 SCFM blower and 81.9 MMBtu/h flare skid packaged system specifically designed to treat the VOCs and Hazardous Air Pollutants (HAP) emissions from the landfill gas.

The multistage centrifugal process blower moves the process stream volume and controls negative air pressure. Manual isolation valves at the blower outlet direct process gases to either the flare for destruction or to the landfill gas upgrading plant. Flares use the natural draft in the stack and density differences to pull in the required air for combustion, breaking apart the chemical bonds of VOCs, converting them into various combinations of carbon dioxide (CO2), water (H2O) and thermal energy.

The system is also equipped with ConiferALERT’s state-of-the-art monitoring and controls. It has a touchscreen and fully automated sequence of operation, as well as integrated hardware and software which allows for remote monitoring and troubleshooting.

- RESULT

Conifer Systems designed a solution to abate VOCs and process biogas in regular landfill operations. With this technology and application, auxiliary fuel use for maintaining heat in the unit was minimal and 98% DRE was achieved.