Oil & Gas

- SITUATION

- SOLUTION

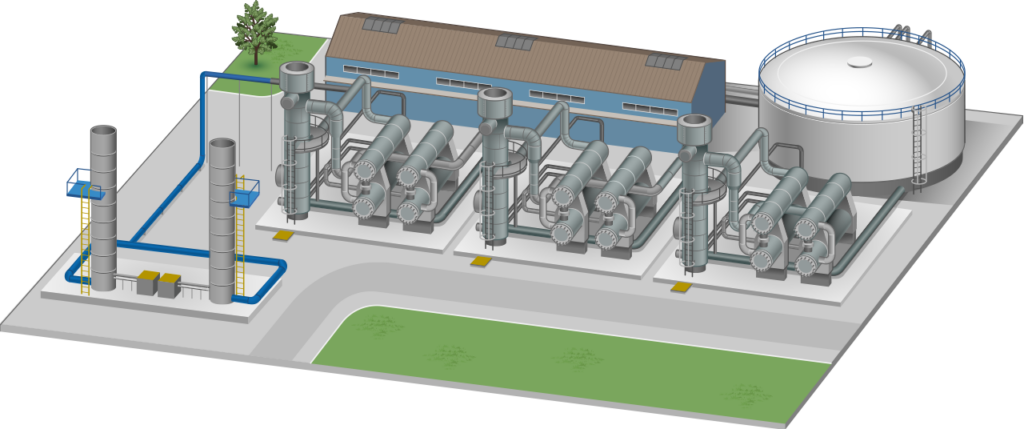

Conifer Systems’ engineers designed a 120 SCFM Direct-Fired Thermal Oxidizer (DFTO) with process isolation dampers in the unit design to shut off the oxidizer from the process stream when it is not in use. The primary damper controls process gas influx during start-up while the secondary damper acts as the on/off actuation. For added safety, it included a flame arrestor to extinguish any fire that may develop.

There was a significant amount of oxygen in the waste gas stream, presenting a risk of combustion and flashback. Our engineers added a dilution process capacity of up to 11 SCFM of inerting nitrogen gas and 102.5 SCFM of fresh air to prevent any explosive conditions.

Heat in the combustion chamber is achieved through a natural gas burner until the chamber is at the optimal temperature to break apart the chemical bonds of volatile organic compounds (VOC) and convert them into combinations of carbon dioxide (CO2) and water vapor (H2O).

A blower supplies additional air required for combustion to the burner and chamber. Upon start-up, the air volume for the system is adjusted from a minimum valve setpoint. As burner demand increases, the blower motor variable frequency drive (VFD) adjusts to the feed rate of the burner and modulates the fan feed rate to allow more cool air in and offset temperature increases.

Once the VOCs are destroyed, the clean air is directed through the exhaust stack then released into the atmosphere.

- RESULT

Conifer Systems designed a customized solution to treat the emissions considering the tank loading operation’s process stream. By incorporating our DFTO into the plant, the client achieved a 98.5% destruction efficiency.