Industries

Municipal Wastewater

- SITUATION

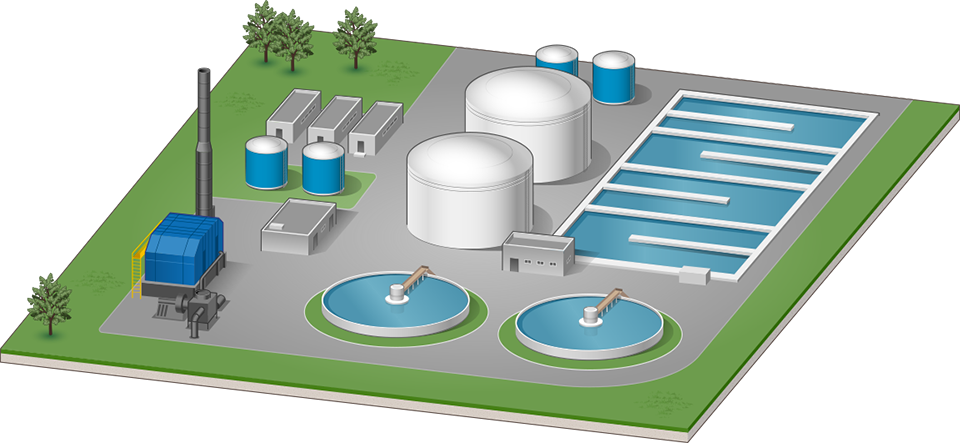

Conifer Systems was asked to find a solution for sludge dryer exhaust in multiple municipal wastewater facilities. Sludge, is a byproduct of the separation of solids and waste in influent streams. It is processed through a heated digester where the odorous waste gases must be treated before being released into the atmosphere.

This client is an engineering firm with a strong presence in the wastewater industry offering a comprehensive range of technologies for screening, thickening, dewatering, and drying industrial wastewater and sludge in the most economical and environmentally sound way.

- SOLUTION

Through the customer’s provided details and their interest in energy recovery, Conifer engineers opted for a 3-canister Regenerative Thermal Oxidizer. This oxidizer uses extremely high heat to clean the exhaust gases and is standard for odor control applications with high moisture content. Through this process, the RTO converts the pollutants in the stream into carbon dioxide and water vapor all while recovering thermal energy that could be used to reduce the cost of operating the equipment.

The VOC laden exhaust stream enters the heat exchange bed using a high-pressure fan before passing through media and going through combustion. Clean gas is then exhausted through another packed media bed which cools the air and heats the media. The final step, which makes the 3-can regenerative thermal oxidizer more efficient, occurs in the final chamber, which traps any remaining VOCs in the “clean” stream, by purging the dirty gases with clean air for further combustion.

Overall, three-canisters RTOs convert the pollutants in the exhaust stream into carbon dioxide and water vapor all while recovering thermal energy. The energy is then used to operate a portion of the unit to reduce the cost of operating the equipment. This unit was built with specific design considerations to handle the siloxanes in the stream. Over-sized heat recovery canisters packed with extra ceramic media were used to avoid the siloxane byproducts from accumulating and blocking the airflow through the media and interfering with heat transfer eventually rendering an RTO to be inoperable. It also included ultra-low NOx burners and extended water drainage and handling capabilities.

- RESULT

Using a three-canister regenerative thermal oxidizer allowed Conifer Systems to provide an effective pollution control solution customized to the needs of this client. This solution was repeated in other facilities with the same application. Conifer Systems has assisted this customer with several different municipal wastewater separation projects. All the units provided for this customer have been specially designed to extend water drainage and handling capabilities. Conifer continues to provide support and new equipment for this customer today.