Medical Sterilization

- SITUATION

A medical sterilization contractor in Puerto Rico required assistance during sterilization of medical and laboratory supplies due to increased regulatory restrictions which required an ethylene oxide (EtO) abatement solution. EtO destruction thresholds tightened from 95% DRE to 99.9%+ DRE, which resulted in sudden and stringent crackdowns on EtO emissions. The new regulations were causing shutdowns for similar facilities and costing hundreds of thousands of dollars of revenue loss per day. This client needed to meet the stricter standards to avoid halting operations.

- SOLUTION

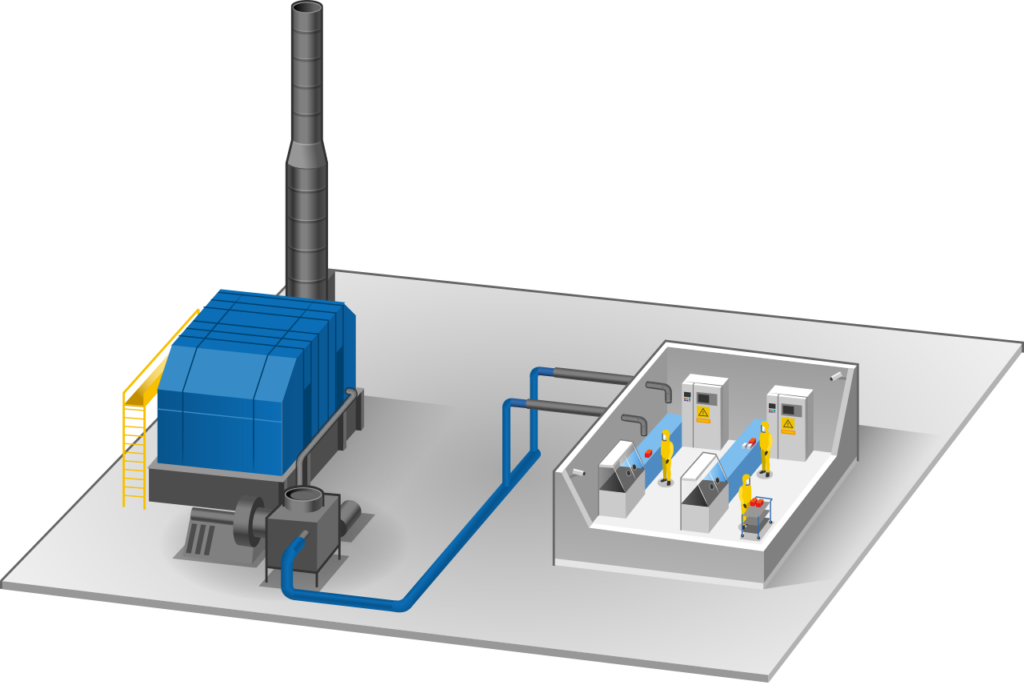

Our team designed and installed a Catalytic Recuperative Oxidizer (CRO) with two heat exchangers to effectively meet the EtO removal requirement and that is capable of processing up to 10,000 SCFM of process gas and dilution air. Using two heat exchangers in this unit maximizes fuel recovery and minimizes the use of auxiliary fuel to reach operational temperatures.

In the CRO, the EtO-laden process stream travels through the preheat exchanger and over the heating elements. Then the hot air volume passes through the catalyst media, and the EtO molecules are destroyed through accelerated thermal oxidation. The molecules become carbon dioxide (CO2), water vapor (H2O) and additional heat which is absorbed by the preheat exchanger as the clean gas passes through the outlet of the abatement system. The excess heat is applied to preheat the next incoming cold, EtO-laden process stream.

A system of variable heat recovery is established to prevent overheating of the incoming air stream. This allows for high heat recovery when the clean gas is released and reduced heat recovery during high-load situations.

With occasional high-VOC loading, an induced draft dilutes the process gas stream to a concentration below 50% of the lower flammability level to prevent the possibility of explosive conditions. This promotes a cleaner, safer and lower maintenance process. Fumes are kept under a vacuum and temperature requirements are lowered, reducing fuel needs and the system’s carbon footprint.

- RESULT

Conifer Systems’ catalytic oxidizer allowed for an essential medical sterilization contractor to continue operating in accordance with regulations by effectively achieving a 99% DRE of the ethylene oxide (EtO) in the exhaust stream. Our innovative solution maximized fuel efficiency, lowered OpEx and reduced the client’s carbon footprint.