Chemical Manufacturing

- SITUATION

- SOLUTION

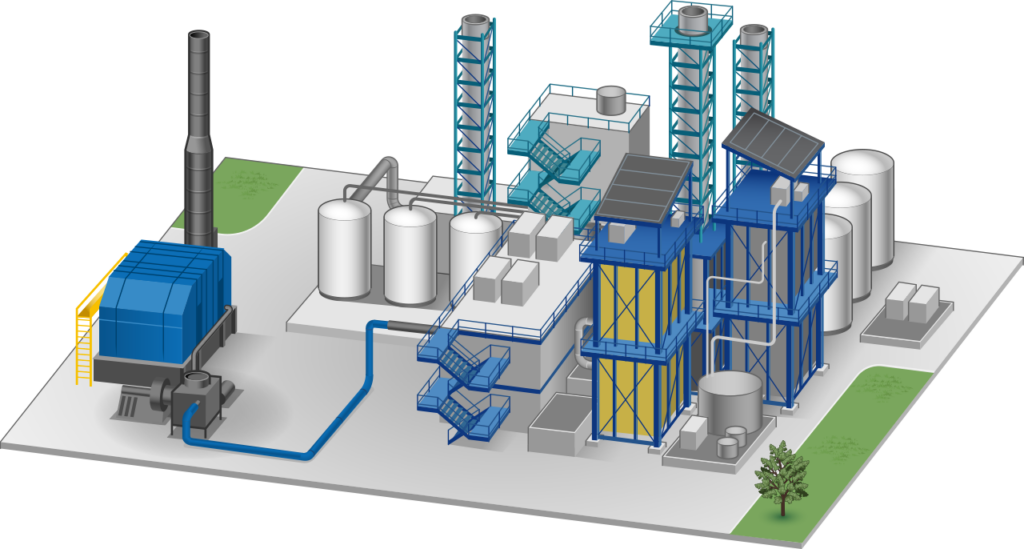

Conifer’s engineering team designed a 2,900 SCFM single-stage, vertical packed-bed gas scrubber to remove the manufacturing plant’s acid gas emissions. The scrubber system included control of the chemical feed pump with variable frequency drive (VFD) and pH controls. A 100-gallon sump tank and a 300-gallon chemical supply tank with a metering pump for the scrubbing solution were added to the tower. The equipment was skid-mounted and pre-assembled for ease of installation and initial start-up.

Single-stage, vertically-packed scrubber towers contain randomly dispersed packing. For this system, we designed the tower to be 3 feet in diameter and 15 feet tall which allowed for 6 feet of packing depth.

This system was made with UV-resistant fiber-reinforced plastic (FRP) for the equipment shell because of its high resistance against corrosive gases and because it is lightweight and electromagnetically neutral.

The system operates through slight negative pressure. Using a system process fan, the stream is pulled upwards through the tower to interact with the scrubbing agent, in this use, a 50% concentration of Sodium Hydroxide (NaOH), or caustic soda. To control the volume and pressure of the exhaust stream, a pressure transmitter and VFD were added to ensure there was no effect on upstream operations. The cleaned gas passes through a mist eliminator at the top of the scrubber tower to collect water droplets before it exhausts into the atmosphere.

- RESULT

Conifer Systems’ customized solution was successful in the destruction of 99% of acid gas emissions and included multiple features that were important to implementation including the skid mount, pre-assembly and several controls specific to the company’s plant.